UTP-80FK

Thermal Printer UTP-80FK

1. Printer usage cautions

• Do not disassemble or attempt to repair the printer.

• Do not allow water to enter the printer.

• Do not drop or jar the printer.

• Fix a paper jam after turning off the power.

• Turn off the power when there is some problem (for example, strange smell or smoke), and

confirm that the trouble is not continuous.

2. Paper usage cautions

The surface of the thermal paper is coated with special chemicals and the characters are

printed out by thermochemical reaction.

• Use specified thermal roll paper.

• Keep in a cool, dry place.

• Keep paper away from hard objects, solvents and vinyl film to prevent paper discoloration.

• Use water-based glue (starch glue, synthetic glue, etc.) when pasting thermal paper.

• Adhesive tape can discolor the thermal paper. Use double-sided tape on the reverse side of

the paper.

• Do not touch the paper with wet hands. Fingerprints may appear on the recording or the

recording may become blurred.

3. Specifications, Parts of the Printer

Specifications

1. Thermal roll paper

Paper type: P-80-25 (Code NO. 000-805-780)

Width of paper: 80 mm

External diameter of roll paper: φ48mm

Length of paper: 25m

2. Environmental conditions

Useable temperature: 0 to +50°C

Storage temperature: -20 to +60°C

Useable and storage humidity: 35 to 85% (no condensation)

APPENDIX

AP-20

Parts

Paper feed slot

Shaft

VR for adjusting printing density

Case Vent DIP switch

Guard plate A

Front panel

Guard plate B

Cutter

Lock lever

Rear panel

Screw hole for fixing case

I/O connector

4. Operation

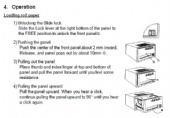

Loading roll paper

1) Unlocking the Slide lock

Slide the Lock lever at the right bottom of the panel to

the FREE position to unlock the front panel1.

2) Pushing the panel

Push the center of the front panel about 2 mm inward.

Release, and panel pops out by about 10mm 2.

3) Pulling out the panel

Place thumb and index finger at top and bottom of

panel and pull the panel forward until you feel some

resistance.

4) Pulling the panel upward

Pull the panel upward. When you hear a click,

continue pulling the panel upward to 90° until you hear

a click again.

APPENDIX

AP-21

5) Attaching roll paper

Insert roll paper into the shaft.

NOTE) Insert the paper so it feeds from above as

shown in the figure at right.

6) Inserting paper

Turn on the POWER and confirm that the PE LED

lights red. Insert paper through paper feed slot. The

PE LED goes off then paper is fed. Feeding stops after

the paper is fed a certain amount.

7) Pulling down the panel

After setting paper, pull the bottom of the panel

downward to fix the panel. Confirm that a click sounds.

8) Pushing in the panel

Place thumb and index finger at bottom and top of

panel and push in the panel.

9) Locking the panel

Push the center of the panel inside the case until it is

deeper than the frame. The front panel should be flush

with the frame.

10) Locking the Slide lock

Slide the Lock lever to the LOCK position to lock the

panel.

Front panel

FEED

SEL

SEL LED

PE LED

Lock lever

Cutter

Paper feed slot

• PE LED: Lights when paper is out.

• SEL LED: Lights in ON-LINE condition.

Data can be received when the light is ON.

• SEL: Chooses ON-LINE or OFF-LINE, alternately.

To temporarily stop printing use this switch to choose OFF-LINE

(SEL LED goes OFF). Push the switch again to re-start printing.

FEED is available on OFF-LINE.

• FEED: Feeds out paper continuously when equipment is in OFF-LINE

condition.

This switch also executes the |